Mtundu wa masterbatch ndi njira yodziwika bwino yopaka utoto wa pulasitiki, yomwe imagwiritsidwa ntchito kwambiri mumakampani opanga mapulasitiki. Chimodzi mwa zizindikiro zofunika kwambiri za masterbatch ndi kufalikira kwake. Kufalikira kumatanthauza kufalikira kofanana kwa utoto mkati mwa zinthu zapulasitiki. Kaya mu jekeseni, kutulutsa, kapena njira zopangira blowing, kufalikira kosayenera kungayambitse kufalikira kosagwirizana kwa mitundu, mizere yosasinthasintha, kapena madontho mu chinthu chomaliza. Nkhaniyi ndi nkhani yofunika kwambiri kwa opanga, ndipo kumvetsetsa zomwe zimayambitsa ndi mayankho ndikofunikira kwambiri kuti zinthu zisunge bwino.

Zomwe Zimayambitsa Kufalikira Kosauka mu Masterbatch ya Mtundu

Kusonkhana kwa Utoto

Masterbatch ndi mtundu wosakanikirana kwambiri wa utoto, ndipo magulu akuluakulu a utoto uwu amatha kukhudza kwambiri kufalikira kwa utoto. Mitundu yambiri, monga titanium dioxide ndi carbon black, imakonda kusonkhana pamodzi. Kusankha mtundu woyenera ndi kukula kwa tinthu ta utoto malinga ndi zomwe zapangidwa komanso njira yopangira ndikofunikira kuti pakhale kufalikira kwa utoto wabwino.

Zotsatira Zamagetsi

Ma masterbatch ambiri saphatikizapo zinthu zotsutsana ndi static. Pamene masterbatch ikasakanizidwa ndi zinthu zopangira, magetsi osasunthika amatha kupangidwa, zomwe zimapangitsa kuti pakhale kusakanikirana kosagwirizana komanso kugawa mitundu kosagwirizana mu chinthu chomaliza.

Chiyerekezo Chosakwanira cha Melt

Ogulitsa nthawi zambiri amasankha ma resini okhala ndi chiŵerengero chachikulu cha kusungunuka ngati chonyamulira cha masterbatch. Komabe, chiŵerengero chachikulu cha kusungunuka sichimakhala chabwino nthawi zonse. Chiŵerengero cha kusungunuka chiyenera kusankhidwa mosamala kuti chigwirizane ndi makhalidwe enieni ndi zofunikira pamwamba pa chinthu chomaliza, komanso makhalidwe a kukonza kwa masterbatch. Chiŵerengero cha kusungunuka chomwe chili chochepa kwambiri chingayambitse kufalikira kosakwanira.

Chiŵerengero Chochepa Chowonjezera

Ogulitsa ena amapanga masterbatch yokhala ndi chiŵerengero chocheperako chowonjezera kuti achepetse ndalama, zomwe zingayambitse kufalikira kosakwanira mkati mwa chinthucho.

Dongosolo Losakwanira Lofalitsa

Zothira mafuta ndi mafuta oyeretsera amawonjezedwa panthawi yopanga masterbatch kuti athandize kuswa magulu a utoto. Ngati zothira mafuta zolakwika zigwiritsidwa ntchito, zingayambitse kufalikira kosakwanira.

Kusagwirizana kwa Kachulukidwe

Ma Masterbatches nthawi zambiri amakhala ndi utoto wokhuthala kwambiri, monga titanium dioxide, womwe uli ndi kuchuluka kwa pafupifupi 4.0g/cm³. Izi zimakhala zazikulu kwambiri kuposa kuchuluka kwa ma resin ambiri, zomwe zimapangitsa kuti masterbatch isungunuke ikasakanikirana, zomwe zimapangitsa kuti mitundu isafalikire mofanana.

Kusankha Kosayenera kwa Wonyamula

Kusankha utomoni wonyamula, womwe umasunga utoto ndi zowonjezera, ndikofunikira kwambiri. Zinthu monga mtundu, kuchuluka, kalasi, ndi index yosungunuka ya chonyamuliracho, komanso ngati chili mu mawonekedwe a ufa kapena pellet, zonse zimatha kukhudza mtundu wa kufalikira komaliza.

Zinthu Zogwirira Ntchito

Momwe masterbatch imagwirira ntchito, kuphatikizapo mtundu wa zida, njira zosakaniza, ndi njira zopangira pelletizing, zimathandiza kwambiri pakufalikira kwake. Zosankha monga kapangidwe ka zida zosakaniza, kasinthidwe ka zomangira, ndi njira zoziziritsira zonse zimakhudza magwiridwe antchito omaliza a masterbatch.

Zotsatira za Njira Zopangira Ma Molding

Njira yeniyeni yopangira zinthu, monga kupanga zinthu pogwiritsa ntchito jakisoni, ingakhudze kufalikira kwa zinthu. Zinthu monga kutentha, kupanikizika, ndi nthawi yogwirira zinthu zingakhudze kufanana kwa kufalikira kwa mitundu.

Zovala za Zipangizo

Zipangizo zomwe zimagwiritsidwa ntchito popanga pulasitiki, monga zomangira zakale, zimatha kuchepetsa mphamvu yodula, zomwe zimafooketsa kufalikira kwa masterbatch.

Kapangidwe ka Nkhungu

Pakuumba jakisoni, malo a chipata ndi mawonekedwe ena a kapangidwe ka nkhungu zimatha kukhudza kapangidwe ka zinthu ndi kufalikira kwa zinthu. Pakutulutsa, zinthu monga kapangidwe ka die ndi kutentha zingakhudzenso mtundu wa kufalikira.

Mayankho Othandizira Kukulitsa Kufalikira mu Masterbatch Yamtundu, mitundu yokhazikika ndi mankhwala

Mukakumana ndi vuto losafalikira bwino, ndikofunikira kuthana ndi vutoli mwadongosolo:

Gwirizanani Pantchito Zonse: Nthawi zambiri, nkhani zofalitsa nkhani sizimangochitika chifukwa cha zinthu kapena njira yokha. Kugwirizana pakati pa anthu onse ofunikira, kuphatikizapo ogulitsa zinthu, mainjiniya a njira, ndi opanga zida, ndikofunikira kwambiri pozindikira ndikuthana ndi zomwe zimayambitsa vutoli.

Konzani Kusankha kwa Utoto:Sankhani utoto wokhala ndi kukula koyenera kwa tinthu tating'onoting'ono ndi mtundu wake womwe ungagwiritsidwe ntchito.

Lamulirani Magetsi Osasunthika:Ikani zinthu zotsutsana ndi kutentha ngati pakufunika kutero kuti mupewe kusakaniza kosagwirizana.

Sinthani Chiyerekezo cha Kusungunuka:Sankhani zonyamulira zokhala ndi chizindikiro chosungunuka chomwe chikugwirizana ndi momwe zinthu zimagwiritsidwira ntchito komanso zofunikira pa malonda.

Kuwerengera Zowonjezera NdemangaOnetsetsani kuti masterbatch yawonjezedwa mokwanira kuti ikwaniritse kufalikira komwe mukufuna.

Sinthani Dongosolo Lofalitsa:Gwiritsani ntchito zothira mafuta ndi zothira mafuta zoyenera kuti muwongolere kusweka kwa ma pigment agglomerates.

Kuchulukana kwa machesi:Ganizirani kuchuluka kwa utoto ndi ma resins onyamula kuti mupewe kusungunuka kwa madzi panthawi yokonza.

Magawo Okonza Zinthu Mwabwino:Sinthani makonda a zida, monga kutentha ndi kasinthidwe ka zomangira, kuti muwonjezere kufalikira.

ZatsopanoMayankho Othandizira Kukulitsa Kufalikira mu Masterbatch Yamtundu

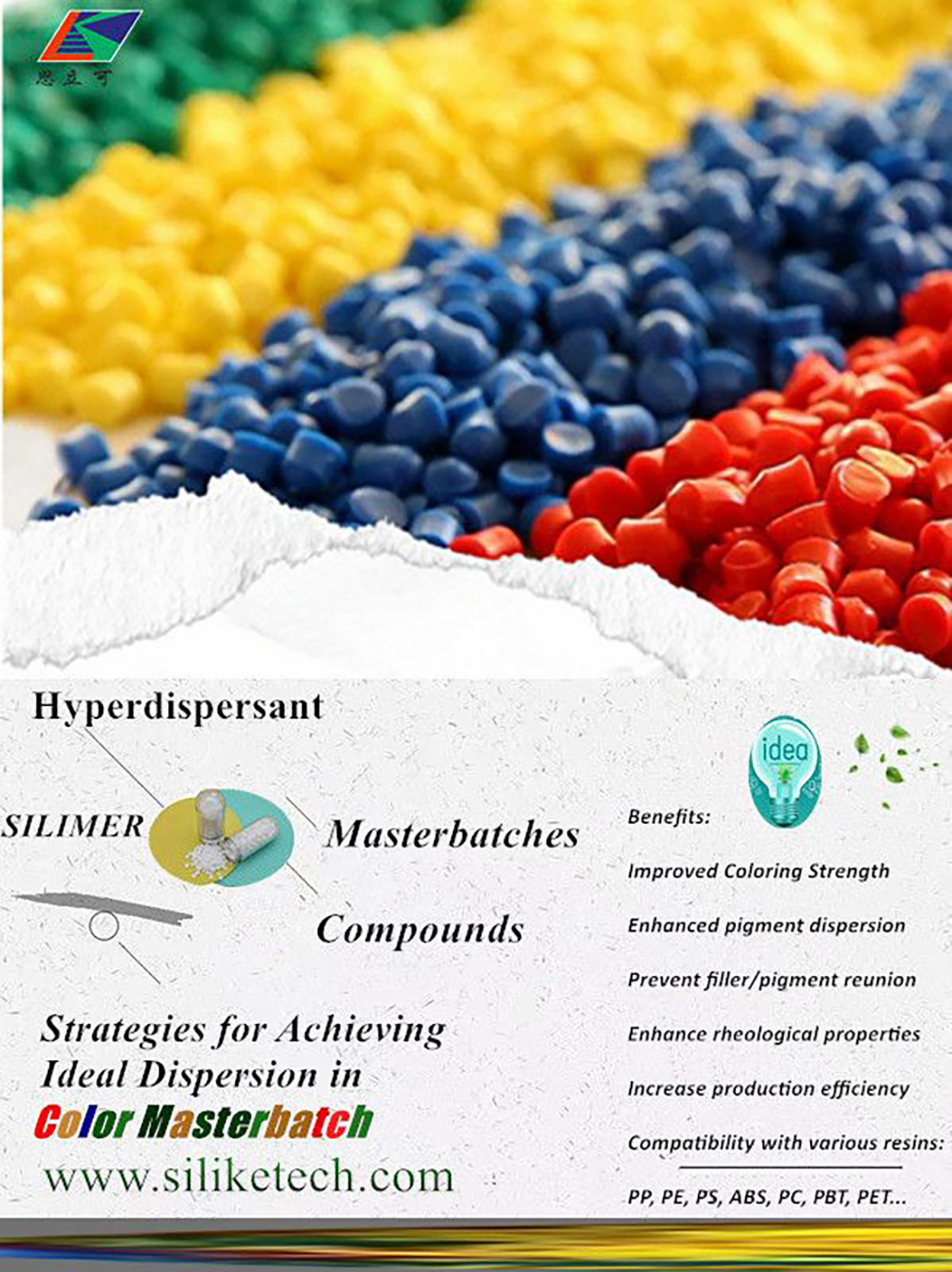

Novel Silicone hyperdispersant, njira yothandiza yothetsera kusalinganika kosagwirizana mu mitundu ya Masterbatches ndiSILIKE SILIMER 6150.

SILIMER 6150ndi sera ya silicone yosinthidwa yomwe imagwira ntchito ngati hyperdispersant yothandiza, yopangidwira makamaka kukweza ubwino wa mitundu yosakanikirana, ma masterbatches, ndi ma compounds. Kaya ndi mtundu umodzi wosakanikirana kapena mitundu yosakanikirana yopangidwa mwaluso, SILIMER 6150 imachita bwino kwambiri pakukwaniritsa zofunikira kwambiri zosakanikirana.

Aubwino wa SILIMER 6150mayankho a color masterbatch:

Kufalikira kwa Utoto Wowonjezereka: SILIMER 6150Zimaonetsetsa kuti utoto ukufalikira mofanana mkati mwa pulasitiki, kuchotsa mikwingwirima kapena madontho amitundu ndikuwonetsetsa kuti mitundu yonse ikuwoneka yofanana.

Mphamvu Yokongoletsa Utoto:Mwa kukonza kufalikira kwa utoto,SILIMER 6150kumawonjezera mphamvu yonse ya utoto, zomwe zimathandiza opanga kuti akwaniritse mtundu womwe akufuna ndi utoto wochepa, zomwe zimapangitsa kuti apange bwino komanso motsika mtengo.

Kupewa Kukumananso kwa Filler ndi Pigment: SILIMER 6150Zimathandiza kuti utoto ndi zodzaza zisagwirizane bwino, kuonetsetsa kuti zifalikira bwino nthawi yonse yokonza.

Makhalidwe Abwino a Rheological: SILIMER 6150Sikuti zimangowonjezera kufalikira kwa zinthu komanso zimawonjezera mphamvu ya rheological ya kusungunuka kwa polima. Izi zimapangitsa kuti ntchito yokonza zinthu ikhale yosalala, kukhuthala kochepa, komanso kuyenda bwino kwa zinthu, zomwe ndizofunikira kwambiri popanga pulasitiki yapamwamba kwambiri.

IKuwonjezeka kwa Kuchita Bwino kwa Ntchito ndi Kuchepetsa NdalamaNdi kufalikira bwino kwa mafupa ndi makhalidwe abwino a rheological,SILIMER 6150kumawonjezera mphamvu yopangira, zomwe zimathandiza kuti nthawi yokonza zinthu ichepe komanso kuchepetsa kutayika kwa zinthu, zomwe pamapeto pake zimachepetsa ndalama zonse zopangira.

Kugwirizana Kwambiri: SILIMER 6150imagwirizana ndi mitundu yosiyanasiyana ya ma resin, kuphatikizapo PP, PE, PS, ABS, PC, PET, ndi PBT, zomwe zimapangitsa kuti ikhale chisankho chabwino kwambiri chogwiritsidwa ntchito m'makampani opanga mapulasitiki a masterbatch ndi compounds.

Wonjezerani kupanga kwanu kwa color masterbatch ndiSILIMER 6150kuti muzitha kufalitsa utoto bwino komanso kuti zinthu zizigwira bwino ntchito. Chotsani mikwingwirima yamitundu ndikuwonjezera mphamvu. Musaphonye—sinthani kufalitsa utoto, chepetsani ndalama, ndikukweza khalidwe lanu la masterbatch.Lumikizanani ndi Silike lero! Foni: +86-28-83625089, Imelo:amy.wang@silike.cn,Pitaniwww.siliketech.comkuti mudziwe zambiri.

Nthawi yotumizira: Ogasiti-15-2024