Chiyambi cha Polyolefins ndi Film Extrusion

Ma polyolefin, gulu la zinthu zazikulu zopangidwa kuchokera ku ma monomers a olefin monga ethylene ndi propylene, ndi mapulasitiki opangidwa komanso ogwiritsidwa ntchito kwambiri padziko lonse lapansi. Kuchuluka kwawo kumachokera ku kuphatikiza kwapadera kwa zinthu, kuphatikizapo mtengo wotsika, kusinthasintha kwabwino, kukhazikika kwa mankhwala, komanso mawonekedwe oyenera. Pakati pa ntchito zosiyanasiyana za ma polyolefin, zinthu zopangidwa ndi mafilimu zimakhala ndi udindo waukulu, zimagwira ntchito yofunika kwambiri pakulongedza chakudya, zophimba zaulimi, zopaka zamafakitale, zinthu zamankhwala ndi zaukhondo, komanso zinthu zogwiritsidwa ntchito tsiku ndi tsiku. Ma resini a polyolefin omwe amagwiritsidwa ntchito kwambiri popanga mafilimu ndi monga polyethylene (PE) - kuphatikizapo Linear Low-Density Polyethylene (LLDPE), Low-Density Polyethylene (LDPE), ndi High-Density Polyethylene (HDPE) - ndi polypropylene (PP).

Kupanga mafilimu a polyolefin kumadalira kwambiri ukadaulo wa extrusion, ndipo Blown Film Extrusion ndi Cast Film Extrusion ndi njira ziwiri zazikulu.

1. Njira Yotulutsira Mafilimu Ophulika

Kutulutsa filimu yopsereza ndi njira imodzi yodziwika bwino yopangira mafilimu a polyolefin. Mfundo yaikulu imaphatikizapo kutulutsa polima wosungunuka molunjika mmwamba kudzera mu die ya annular, ndikupanga parison yopyapyala yokhala ndi makoma ochepa. Pambuyo pake, mpweya wopanikizika umalowetsedwa mkati mwa parison iyi, zomwe zimapangitsa kuti ipse kukhala thovu lokhala ndi mainchesi akulu kwambiri kuposa a die. Pamene thovulo likukwera, limaziziritsidwa mwamphamvu ndikulimba ndi mphete yakunja ya mpweya. Thovulo loziziritsidwa limagwetsedwa ndi ma nip rollers (nthawi zambiri kudzera mu chimango chogwa kapena A-frame) kenako limakokedwa ndi ma traction rollers asanakulungidwe pa roll. Njira yopangira filimu yopsereza nthawi zambiri imapanga mafilimu okhala ndi biaxial orientation, zomwe zikutanthauza kuti amasonyeza bwino makhalidwe a makina mu njira yonse ya makina (MD) ndi njira yopingasa (TD), monga mphamvu yokoka, kukana kung'ambika, ndi mphamvu ya impact. Kukhuthala kwa filimu ndi makhalidwe a makina zitha kulamulidwa posintha chiŵerengero cha kuphulika (BUR - chiŵerengero cha mainchesi a thovu mpaka mainchesi a die) ndi chiŵerengero cha kutsitsa (DDR - chiŵerengero cha liwiro lotenga mpaka liwiro lotulutsa).

2. Njira Yotulutsira Mafilimu Osewerera

Kutulutsa filimu ya Cast ndi njira ina yofunika kwambiri yopangira mafilimu a polyolefin, makamaka yoyenera kupanga mafilimu omwe amafuna mawonekedwe apamwamba kwambiri (monga kumveka bwino, kunyezimira kwambiri) komanso makulidwe ofanana. Munjira iyi, polima wosungunuka amatulutsidwa mopingasa kudzera mu T-die yathyathyathya, yotchinga, ndikupanga ukonde wosungunuka wofanana. Ubweya uwu umakokedwa mwachangu pamwamba pa mipukutu imodzi kapena zingapo zozizira kwambiri, zozizira mkati. Kusungunuka kumauma mwachangu ikakhudzana ndi pamwamba pa mipukutu yozizira. Mafilimu a Cast nthawi zambiri amakhala ndi mawonekedwe abwino kwambiri, omveka bwino, komanso otsekeka bwino kutentha. Kuwongolera bwino pa die lip gap, kutentha kwa mipukutu yozizira, ndi liwiro lozungulira kumalola kuwongolera molondola makulidwe a filimu ndi mtundu wake.

Mavuto 6 Apamwamba Okhudza Kutulutsa Mafilimu a Polyolefin

Ngakhale kuti ukadaulo wotulutsa zinthu wafika pamlingo wapamwamba, opanga nthawi zambiri amakumana ndi mavuto ambiri pakupanga mafilimu a polyolefin, makamaka akamayesetsa kuti apange zinthu zambiri, azigwira bwino ntchito, azigawo zopyapyala, komanso akamagwiritsa ntchito ma resin atsopano ogwira ntchito bwino. Mavuto amenewa samangokhudza kukhazikika kwa kupanga komanso amakhudza mwachindunji mtundu wa zinthu zomaliza komanso mtengo wake. Mavuto akuluakulu ndi awa:

1. Kusweka kwa Melt (Sharkskin): Ichi ndi chimodzi mwa zolakwika zomwe zimafala kwambiri pakutuluka kwa filimu ya polyolefin. Mwa ma microscopic, zimaonekera ngati ma ripples ozungulira nthawi ndi nthawi kapena malo osasunthika pa filimuyo, kapena pazochitika zazikulu, kusokonekera kwakukulu. Kusweka kwa kusungunuka kumachitika makamaka pamene kuchuluka kwa kusungunuka kwa polymer komwe kumatuluka mu die kumaposa mtengo wofunikira, zomwe zimapangitsa kuti kusuntha kwa stick-slip pakati pa khoma la die ndi kusungunuka kwakukulu, kapena pamene kupsinjika kwa extensional pa die exit kumaposa mphamvu ya kusungunuka. Chilema ichi chimawononga kwambiri mawonekedwe a filimuyo (kumveka bwino, kunyezimira), kusalala kwa pamwamba, ndipo kumathanso kuwononga mawonekedwe ake amakina ndi zotchinga.

2. Kusungunuka kwa Madontho a Madzi / Kusungunuka kwa Madontho: Izi zikutanthauza kusonkhanitsa pang'onopang'ono kwa zinthu zowononga ma polima, magawo ochepa a mamolekyu, zowonjezera zosabalalika bwino (monga utoto, zinthu zotsutsana ndi static, zinthu zotsetsereka), kapena ma gels kuchokera ku utomoni m'mphepete mwa milomo ya die kapena mkati mwa denga la die. Ma depositi awa amatha kuchoka panthawi yopanga, kuipitsa pamwamba pa filimu ndikuyambitsa zolakwika monga ma gels, mikwingwirima, kapena mikwingwirima, motero zimakhudza mawonekedwe ndi mtundu wa chinthucho. Pazochitika zazikulu, kusungunuka kwa ma die kumatha kutseka kutuluka kwa die, zomwe zimapangitsa kuti pakhale kusiyana kwa ma gauge, kung'ambika kwa filimu, ndipo pamapeto pake kukakamiza kutsekedwa kwa mzere wopanga kuti ayeretse ma die, zomwe zimapangitsa kuti kutayika kwakukulu pakugwira ntchito bwino kwa kupanga ndi kutayika kwa zinthu zopangira.

3. Kuthamanga Kwambiri ndi Kusintha kwa Mphamvu Yotulutsa: Pazifukwa zina, makamaka pokonza ma resini okhala ndi kukhuthala kwakukulu kapena kugwiritsa ntchito mipata yaying'ono ya die, kuthamanga mkati mwa dongosolo lotulutsa (makamaka pamutu wa extruder ndi die) kumatha kukhala kwakukulu kwambiri. Kuthamanga kwakukulu sikungowonjezera kugwiritsa ntchito mphamvu zokha komanso kumabweretsa chiopsezo ku moyo wautali wa zida (monga screw, barrel, die) ndi chitetezo. Kuphatikiza apo, kusinthasintha kosakhazikika kwa kuthamanga kwa extrusion kumayambitsa kusinthasintha kwa kutulutsa kwamadzimadzi, zomwe zimapangitsa kuti makulidwe a filimu asafanane.

4. Kuchuluka kwa Magwiridwe Antchito: Pofuna kupewa kapena kuchepetsa mavuto monga kusweka kwa melting ndi kufa, opanga nthawi zambiri amakakamizika kuchepetsa liwiro la screw ya extruder, motero amachepetsa kutulutsa kwa mzere wopanga. Izi zimakhudza mwachindunji magwiridwe antchito opanga komanso mtengo wopanga pa unit iliyonse ya chinthu, zomwe zimapangitsa kuti zikhale zovuta kukwaniritsa zosowa za msika zamakanema akuluakulu komanso otsika mtengo.

5. Kuvuta kwa Kulamulira Gauge: Kusakhazikika kwa kayendedwe ka kusungunuka, kufalikira kwa kutentha kosagwirizana pa die, ndi kusonkhana kwa die zonse zingathandize kusintha makulidwe a filimu, mopingasa komanso motalikirapo. Izi zimakhudza momwe filimuyo imagwirira ntchito komanso momwe imagwiritsidwira ntchito kumapeto.

6. Kusintha kwa Resin Kovuta: Mukasintha mitundu yosiyanasiyana kapena magiredi a polyolefin resins, kapena mukasintha mitundu ya masterbatches, zinthu zotsalira zomwe zidagwiritsidwa ntchito kale nthawi zambiri zimakhala zovuta kuzichotsa kwathunthu kuchokera ku extruder ndikuzifa. Izi zimapangitsa kuti zinthu zakale ndi zatsopano zisakanikirane, kupanga zinthu zosinthira, kukulitsa nthawi yosinthira, ndikuwonjezera kuchuluka kwa zinyalala.

Mavuto ofala awa okonza zinthu amalepheretsa khama la opanga mafilimu a polyolefin kuti awonjezere ubwino wa zinthu ndi magwiridwe antchito, komanso amalepheretsa kugwiritsa ntchito zipangizo zatsopano ndi njira zamakono zopangira zinthu. Chifukwa chake, kufunafuna mayankho ogwira mtima kuti athetse mavutowa ndikofunikira kwambiri pakukula kosatha komanso kwathanzi kwa makampani onse opanga mafilimu a polyolefin.

Mayankho a Njira Yotulutsira Mafilimu a Polyolefin: Zothandizira Polima Polima (PPAs)

Zothandizira Polima Polima (PPAs) ndi zowonjezera zomwe phindu lake lalikulu ndikuwongolera machitidwe a rheological a polymer melts panthawi yotulutsa ndikusintha momwe zimagwirizanirana ndi zida, potero kuthana ndi zovuta zosiyanasiyana zokonza ndikuwonjezera magwiridwe antchito opanga komanso mtundu wa zinthu.

1. Ma PPA okhala ndi Fluoropolymer

Kapangidwe ka Mankhwala ndi Makhalidwe: Pakadali pano awa ndi gulu la ma PPA omwe amagwiritsidwa ntchito kwambiri, okhwima paukadaulo, komanso ogwira mtima kwambiri. Nthawi zambiri ndi ma homopolymer kapena ma copolymer otengera ma fluoroolefin monomers monga vinylidene fluoride (VDF), hexafluoropropylene (HFP), ndi tetrafluoroethylene (TFE), ndipo ma fluoroelastomers ndi omwe amayimira kwambiri. Maunyolo a ma molekyulu a ma PPA awa ali ndi ma bond CF olemera kwambiri, omwe amapereka mphamvu zapadera za physicochemical: mphamvu yochepa kwambiri pamwamba (monga polytetrafluoroethylene/Teflon®), kukhazikika kwabwino kwa kutentha, komanso kusakhala bwino kwa mankhwala. Chofunika kwambiri, ma PPA a fluoropolymer nthawi zambiri samagwirizana bwino ndi ma polyolefin matrices osakhala a polar (monga PE, PP). Kusagwirizana kumeneku ndikofunikira kwambiri kuti asamukire bwino ku zitsulo za die, komwe amapanga utoto wopaka mafuta.

Zogulitsa Zoyimira: Makampani otsogola pamsika wapadziko lonse wa ma PPA a fluoropolymer akuphatikizapo mndandanda wa Chemours' Viton™ FreeFlow™ ndi mndandanda wa 3M's Dynamar™, omwe ali ndi gawo lalikulu pamsika. Kuphatikiza apo, mitundu ina ya fluoropolymer kuchokera ku Arkema (mndandanda wa Kynar®) ndi Solvay (Tecnoflon®) imagwiritsidwanso ntchito ngati, kapena ndi zigawo zazikulu mu, mapangidwe a PPA.

2. Zothandizira Kukonza Zinthu Zochokera ku Silicone (PPAs)

Kapangidwe ka Mankhwala ndi Makhalidwe Ake: Zigawo zazikulu zogwira ntchito mu gulu ili la ma PPA ndi ma polysiloxanes, omwe nthawi zambiri amatchedwa ma silicones. Msana wa polysiloxane umakhala ndi ma atomu a silicon ndi okosijeni (-Si-O-), omwe ali ndi magulu achilengedwe (nthawi zambiri methyl) omangiriridwa ku ma atomu a silicon. Kapangidwe kapadera ka mamolekyulu kameneka kamapereka zinthu za silicone zokhala ndi mphamvu yochepa kwambiri pamwamba, kukhazikika kwa kutentha kwabwino, kusinthasintha kwabwino, komanso mphamvu zosamatira kuzinthu zambiri. Mofanana ndi ma PPA a fluoropolymer, ma PPA ochokera ku silicone amagwira ntchito posamukira ku zitsulo za zida zopangira kuti apange gawo lopaka mafuta.

Makhalidwe Ogwiritsira Ntchito: Ngakhale kuti ma PPA a fluoropolymer ndi omwe amalamulira gawo la polyolefin film extrusion, ma PPA okhala ndi silicone amatha kuwonetsa zabwino zapadera kapena kupanga zotsatira zogwirizana akagwiritsidwa ntchito pazinthu zinazake kapena mogwirizana ndi machitidwe enaake a resin. Mwachitsanzo, amatha kuganiziridwa kuti agwiritsidwe ntchito pofunikira ma coefficients otsika kwambiri a kukangana kapena komwe mawonekedwe enaake a pamwamba amafunidwa pa chinthu chomaliza.

Mukukumana ndi Mavuto Oletsa Fluoropolymer kapena Mavuto Okhudza Kupereka kwa PTFE?

Konzani Mavuto Okhudza Kutulutsa Mafilimu a Polyolefin ndi Mayankho a PPA a PFAS-Free-Zowonjezera za SILIKE's Fluorine Polymer

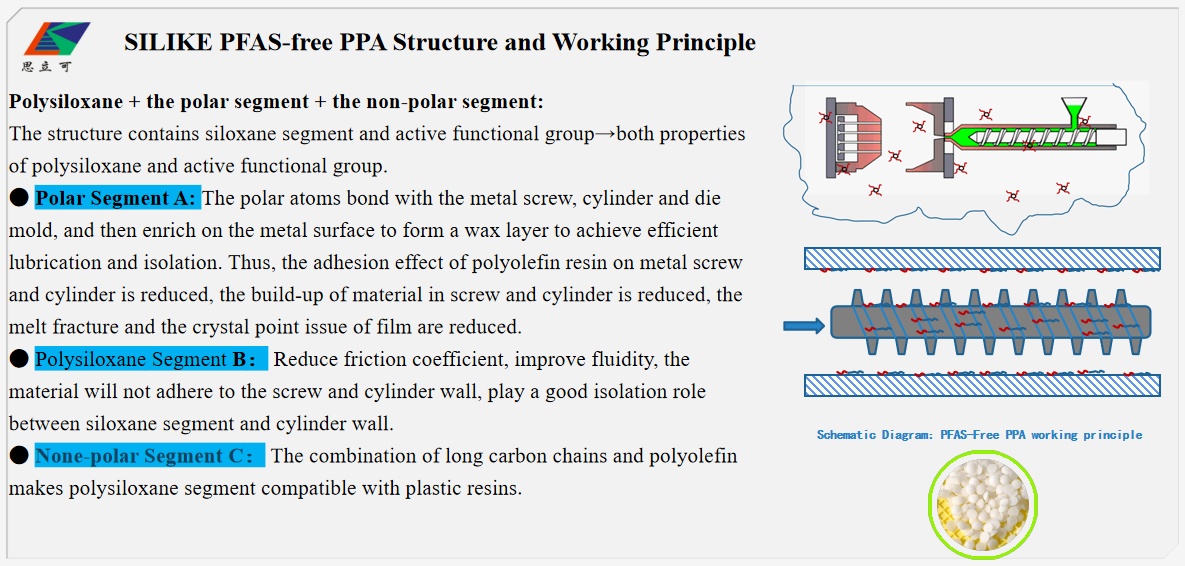

SILIKE imagwiritsa ntchito njira yodziwira mavuto ndi zinthu zake za mndandanda wa SILIMER, zomwe zimapereka zatsopano.Zothandizira polima zopanda PFAS (PPAS)Mzere wonse wazinthuzi uli ndi ma PPA opanda PFAS okwanira 100%.Zowonjezera za polymer za PPA zopanda fluorinendiMa masterbatches a PPA opanda PFAS komanso opanda fluorine.Bykuthetsa kufunikira kwa zowonjezera za fluorine, kukonza kumeneku kumathandiza kwambiri kukonza njira zopangira LLDPE, LDPE, HDPE, mLLDPE, PP, ndi njira zosiyanasiyana zotulutsira mafilimu a polyolefin. Zimagwirizana ndi malamulo aposachedwa azachilengedwe komanso zimathandizira kupanga bwino, kuchepetsa nthawi yogwira ntchito, komanso kukonza mtundu wonse wa zinthu. Ma PPA opanda PFAS a SILIKE amabweretsa zabwino ku chinthu chomaliza, kuphatikizapo kuchotsa kusweka kwa sharkskin, kusalala bwino, komanso khalidwe labwino kwambiri la pamwamba.

Ngati mukulimbana ndi zotsatira za kuletsa kwa fluoropolymer kapena kusowa kwa PTFE mu njira zanu zotulutsira ma polymer, SILIKE imapereka.njira zina m'malo mwa fluoropolymer PPAs/PTFE, Zowonjezera zopanda PFAS zopangira mafilimuzomwe zakonzedwa kuti zikwaniritse zosowa zanu, popanda kusintha kwa njira zomwe zikufunika.

Nthawi yotumizira: Meyi-15-2025